- Home Page

- Company Profile

-

Our Products

- Chemical Reactor

- Solvent Plant Equipment

- Ceramic Industrial Products

- Fabricated Equipment

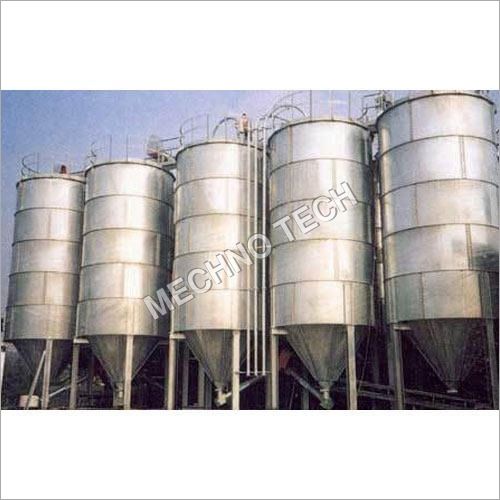

- Industrial Silos

- Axial Fans

- Cooling Tower

- Cleaning Equipment

- Electric Kilns

- Automatic Spray Booth

- SS Axial Fans

- Mild Steel Tanks

- Industrial Blowers

- Heat Exchanger

- Storage Vessels and Tanks

- SS Pressure Vessels

- Pressure Filters Vessels

- Pressure Vessels

- Vacuum Catch Pots Vessels

- Low Pressure Vessels

- Jacketed Pressure Vessels

- Air Receivers Tank Vessels

- Stainless Steel Storage Tank

- SS Storage Vessels

- Customized SS Storage Tanks

- Mild Steel Storage Vessels

- MS Storage Tanks

- SS Storage Tanks

- High Pressure Vessels

- Receiver Tanks

- Industrial Receiver Vessels

- Agitated Vessels

- Stainless Steel Tanks

- Storage Tanks and Vessels

- Contact Us

Call us:

08045804471

Air Receiver Tank

120000 INR/Unit

Product Details:

- Product Type Vertical Air Receiver Tank

- Material Mild Steel (MS)

- Capacity 500 Liters

- Finish Powder Coated

- Color Blue

- Capability Withstand high working pressure up to 12 Bar

- Dimension (L*W*H) Approx. 950 mm (Diameter) x 2200 mm (Height)

- Click to View more

X

Air Receiver Tank Price And Quantity

- 1 Unit

- 120000 INR/Unit

Air Receiver Tank Product Specifications

- Approx. 950 mm (Diameter) x 2200 mm (Height)

- Withstand high working pressure up to 12 Bar

- Approx. 185 Kg

- 500 Liters

- Compressed air storage for industrial and commercial applications

- Used as air receiver for compressors and pneumatic systems

- Mild Steel (MS)

- 2200 mm

- Depends on tank size and working pressure

- Elliptical dished end

- Vertical Air Receiver Tank

- Powder Coated

- Blue

Air Receiver Tank Trade Information

- 10 Unit Per Day

- 1 Week

Product Description

Air Receiver Tank

An Air Receiver Tank is a tank that stores the compressed air once it is out of the compressor. It helps in keeping a reserve of the compressed air for future use without operating or using the compressor again. The offered tank is an important part of the compressed air system. It helps in optimizing and improving the performance of the plant. The offered Air Receiver Tank is very useful and highly efficient. It can be installed in the system easily.

Technical Specification

| Shape | Vertical |

| Usage/Application | Industrial |

| Material | Mild Steel |

| Brand | Mechno Tech |

| Volume/Capacity | 20 - 280 L |

| Frequency | 50 - 60 Hz |

Reliable Compressed Air Storage

Designed for both industrial and commercial applications, this air receiver tank provides stable storage for compressed air generated by compressors. Its robust construction and powder-coated finish protect against corrosion, ensuring long-term operational efficiency and safety for pneumatic systems.

Built to International Standards

Manufactured in strict adherence to ASME Sec VIII Div 1 and IS 2825 standards, this tank guarantees optimal performance and safety. Welded construction and elliptical dished ends add strength, while rigorous pressure testing up to 18 Bar confirms its reliability under demanding conditions.

Customizable to Meet Your Needs

With customizable working pressures and production capacities determined by tank size, this floor-mounted air receiver tank offers versatile solutions. Connection ports for all essential functions support integration into various compressed air systems for enhanced flexibility and usability.

FAQs of Air Receiver Tank:

Q: How does the air receiver tank enhance the efficiency of compressed air systems?

A: The air receiver tank stores compressed air, minimizing fluctuations in pressure, reducing compressor startup cycles, and providing a reserve during peak demands. This results in more efficient system operation and energy savings.Q: What process is used to ensure corrosion resistance in the tank?

A: Internal and external powder coating is applied to the mild steel construction, forming a protective layer against rust and corrosion, which extends the service life and reliability of the tank.Q: Where is the air receiver tank typically installed?

A: It is floor-mounted on four legs and positioned near compressors within industrial or commercial facilities, enabling easy integration with pneumatic systems due to its various connection ports.Q: What is the benefit of the elliptical dished end design?

A: The elliptical dished end improves the tanks structural strength and pressure resistance, reducing the risk of stress points and potential failures under high pressure.Q: When should the air receiver tank undergo pressure testing?

A: Pressure testing should be performed after installation and during routine maintenance to ensure the tank maintains integrity and can safely operate up to the specified 18 Bar testing pressure.Q: How is the production capacity of the air receiver tank determined?

A: Production capacity varies based on the tanks size and intended working pressure, allowing manufacturers to offer tailored solutions suitable for different operational requirements.Q: What are the primary usage applications for this tank?

A: It is primarily used for storing compressed air in industrial and commercial environments as part of compressor systems and pneumatic tools or processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email