- Home Page

- Company Profile

-

Our Products

- Chemical Reactor

- Solvent Plant Equipment

- Ceramic Industrial Products

- Fabricated Equipment

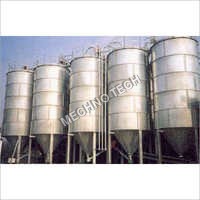

- Industrial Silos

- Axial Fans

- Cooling Tower

- Cleaning Equipment

- Electric Kilns

- Automatic Spray Booth

- SS Axial Fans

- Mild Steel Tanks

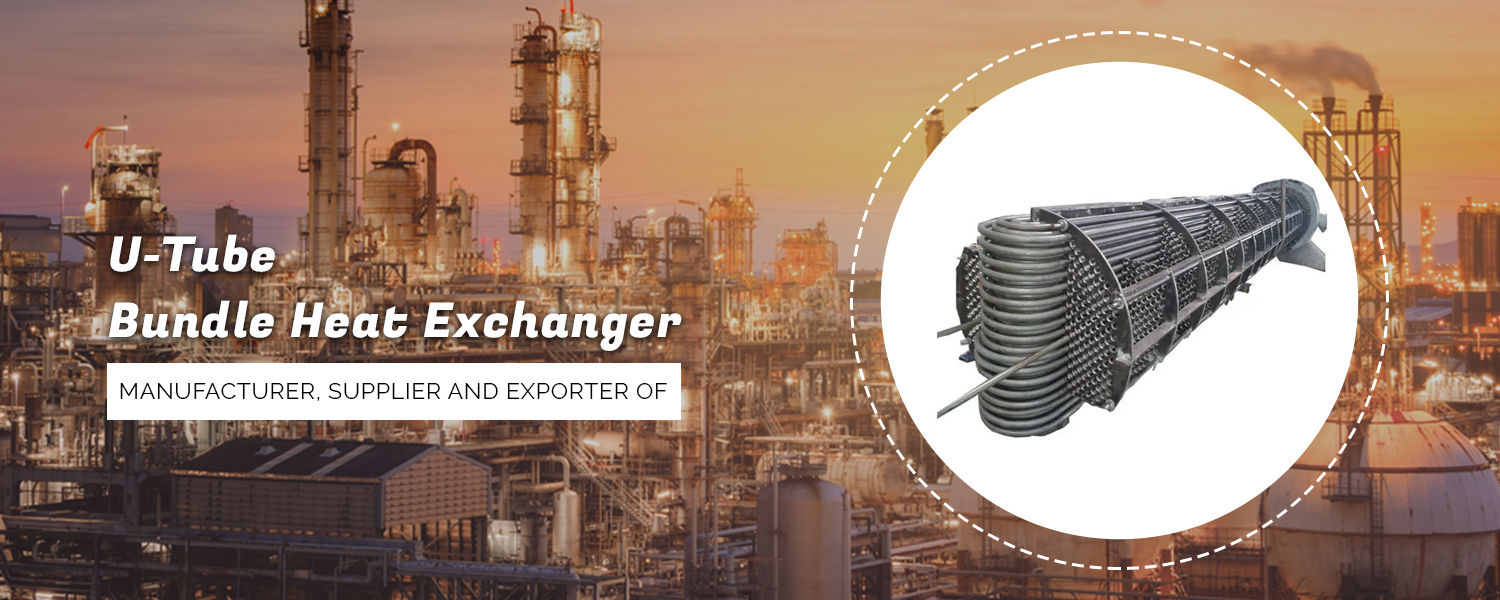

- Industrial Blowers

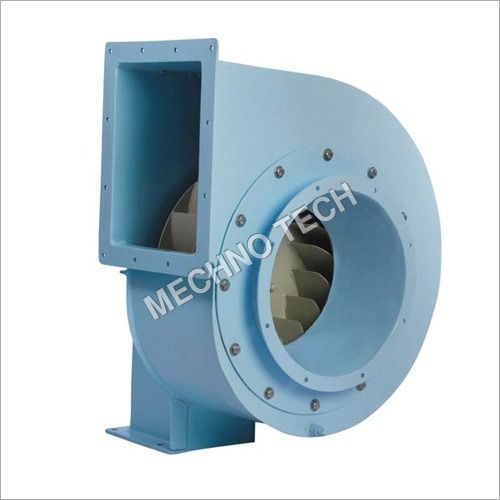

- Heat Exchanger

- Storage Vessels and Tanks

- SS Pressure Vessels

- Pressure Filters Vessels

- Pressure Vessels

- Vacuum Catch Pots Vessels

- Low Pressure Vessels

- Jacketed Pressure Vessels

- Air Receivers Tank Vessels

- Stainless Steel Storage Tank

- SS Storage Vessels

- Customized SS Storage Tanks

- Mild Steel Storage Vessels

- MS Storage Tanks

- SS Storage Tanks

- High Pressure Vessels

- Receiver Tanks

- Industrial Receiver Vessels

- Agitated Vessels

- Stainless Steel Tanks

- Storage Tanks and Vessels

- Contact Us

Call us:

08045804471

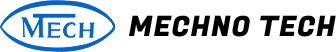

Enhance Your Industrial Productivity, Utilizing Our Range of SS Storage Tank, Centrifugal Blower, SS Reactor, Air Receiver, Cement Silos, Heat Exchanger, Vessels, MS Storage Tank, SS Silos, SS Condenser and More...

We, Mechno Tech are the reflection of perfection and progression. In the business since 2009, we have been contributing to diversified industrial areas that deals in thermal power plants, structure fabrication, etc., with our extensive range of equipment by working as a manufacturer & exporter. Our enterprise offers the finest performing products at highly affordable prices. The offered assortment encompasses Heat Exchanger, Vessels, MS Storage Tank, SS Storage Tank, Centrifugal Blower, SS Reactor, Air Receiver, Cement Silos, SS Silos, SS Condenser and many more items. The equipment delivered by us receives endless compliments for their respective functionality, results and operations. That is why, they always stay in high demands amongst the industrialists & individuals and, we keep fulfilling these demands as per given commitments and promises.

Our Clientele

With intentions of setting new

benchmarks in the respective domain, we are constantly making our

production and services more & more reliable for the respective

customers. Besides this, we work completely for the satisfaction of

clients for which, our operations are managed in client-centric manner.

We practice ethical business deals with them, provide the best offers

and accept payments through all available platforms, online &

offline. The list of our precious clients contains names such as:

- Glocon Inc, NJ. USA

- H & R Johnson (I) Ltd., Dewas

- Ranbaxy Lab Ltd., Dewas

- M.P. Power Generating Co Ltd (Satpura Thermal Power Station) Sarni

- Khaitan Chemical & Fertilizer., Indore, Jhansi, Nimrani, Maxi, Ratlam

- E I D Parry (I) Ltd. Dewas

- Clihattisgarh State Electricity Board(Hesdeo Thennal Power House) Korba

- Ambika Solvcx Ltd, Indore, Jaora. Akola

- Panyware Roca Pvt. Ltd, Dewas

- Gabrial India Ltd Dewas

- Ramco Industries Ltd., Maksi

- Kriti Industries Ltd, Dewas

- Caparo Tubes India, Dewas

- Dewas Soya Industries Ltd, Dewas

- Shree Synthetics Ltd, Ujjain

- S T I (Saitoh) India Ltd, Dewas

- Navin Flourine International Ltd.,Dewas

- IPCA Laboratories Ltd., Ratlam

- S. Kumars Ltd., Dewas

Quality Management

We adhere to national industrial standards and guidelines for producing the top-notch quality of equipment like Heat Exchanger, Vessels, MS Storage Tank, SS Storage Tank, Centrifugal Blower, SS Reactor, Air Receiver, Cement Silos, SS Silos, SS Condenser, etc. The entire organizational production processes at our unit are in compliance with ISO 9001:2008 certification. The major factors that keep our production

unique, authentic and quality-driven are the work approaches adopted by

us & upgraded from time to time so that, a better range can be

offered by us. Moreover, the overall process is monitored by our quality

experts from procurement of raw material to final finishing. The end

product is carefully inspected on the basis of quality parameters such

as Match moment, Static balancing, Dynamic balancing, In house and on

site vibration analysis, Cantilever load testing, Construction,

Pressure endurance, Resistance to rust and Durability. Our enterprise follows very stringent quality

inspection procedures to ensure that our delivered items are in their

best condition. These procedures are:

- Design Confirmation: The final designing or drawing of equipment is checked as per the specific requirements.

- Documentation Control: The approval for designing, welding, performance tests, etc. are taken from clients.

- Materials Control: The raw material procured for fabrication is precisely tested by our Metallurgy lab for generating the best results.

- Layout Inspection: The production heads check the cutting & marking layouts before putting the material into cutting, rolling, welding & other processes.

- Stage Inspection: After the completion of entire production, the respective quality inspection heads assure that the finally prepared item meets its specified quality characteristics. The overall process carried out at our unit contains Non-destructive testing which is based on:

- Visual Inspection

- Ultrasonic testing

- Radiographic testing

- Liquid penetration testing

- Magnetic particle testing

Diverse Industries we Cater to

Through our growth focused work strategies, we have spread our

work network in different areas of manufacturing. A large number of

renowned companies are associated with us today from the sectors like thermal

power stations, chemical plants, sugar factories, soya plants, textile

manufacturing units, fertilizer plants, ceramic & sanitaryware

manufacturing units and more.

Quality Management

Over the period, we have proven ourselves as the most quality conscious manufacturer who never compromises with the quality of even a single item including Chemical Reactor, Industrial Silos,

Infrastructure & Facilities

The ultra-advanced infrastructural facilities of ours at of Mechno Tech are one of the major USPs from day one. We have a capacious manufacturing unit, which is divided

Machining & FRP Division

We have a highly instrumental machining division with various sizes of lathes, milling, shaper, dynamic balancing, grinder, power hacksaw and other machines.

Product Galley

-

CGMP Reactors -

Duplex Filters -

Jacketed Reactors -

Toaster D Solvent -

Dust Extractors -

Cyclone Separator -

High Speed Blunger -

Kiln Cars -

Low Speed Blungers -

SS Impeller -

Industrial Chimneys -

SS Dish End -

Industrial Silos -

SS Storage Silos -

Industrial SS Silos -

Industrial Axial Fans -

Closed Loop Cooling Tower -

Cip System -

Electric Kilns -

Automatic Spray Booth -

SS Axial Fans -

Mild Steel Tank -

2 KL Mild Steel Tank -

Ventilation Blowers -

Fume Exhaust Blowers -

Low Pressure Blowers -

CGMP Heat Exchanger -

Shell and Tube Type Heat Exchanger -

SS Heat Exchanger -

SS Pressure Vessels -

Stainless Steel Storage Tank -

Air Receivers Tank Vessels -

SS 316 Stainless Steel Storage Tank -

Stainless Steel Vessels -

SS 304 Storage Tank

Our Happy Client