- Home Page

- Company Profile

-

Our Products

- Chemical Reactor

- Solvent Plant Equipment

- Ceramic Industrial Products

- Fabricated Equipment

- Industrial Silos

- Axial Fans

- Cooling Tower

- Cleaning Equipment

- Electric Kilns

- Automatic Spray Booth

- SS Axial Fans

- Mild Steel Tanks

- Industrial Blowers

- Heat Exchanger

- Storage Vessels and Tanks

- SS Pressure Vessels

- Pressure Filters Vessels

- Pressure Vessels

- Vacuum Catch Pots Vessels

- Low Pressure Vessels

- Jacketed Pressure Vessels

- Air Receivers Tank Vessels

- Stainless Steel Storage Tank

- SS Storage Vessels

- Customized SS Storage Tanks

- Mild Steel Storage Vessels

- MS Storage Tanks

- SS Storage Tanks

- High Pressure Vessels

- Receiver Tanks

- Industrial Receiver Vessels

- Agitated Vessels

- Stainless Steel Tanks

- Storage Tanks and Vessels

- Contact Us

Call us:

08045804471

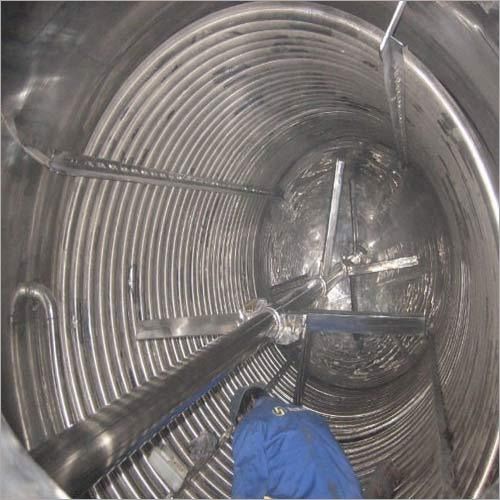

CGMP Reactors

Product Details:

- Product Type CGMP Reactors

- General Use Pharmaceutical, Chemical, and Food Processing Industries

- Material Stainless Steel (SS316/SS304)

- Type Vertical Cylindrical

- Capacity 100 L - 10,000 L (customizable)

- Weight (kg) Variable as per capacity

- Computerized No

- Click to View more

X

CGMP Reactors Price And Quantity

- 1 , , Unit

CGMP Reactors Product Specifications

- Jacketed (Steam/Electric/Thermic Fluid)

- Mirror/Matte Polished Stainless Steel

- Export Standard Wooden Packing/Custom Export Packing

- No

- 100 L - 10,000 L (customizable)

- Yes

- Variable as per capacity

- Customized as per capacity and user requirement

- Optional

- Vertical Cylindrical

- ABB/Siemens/Equivalent Premium Efficiency Motor

- Pharmaceutical, Chemical, and Food Processing Industries

- CGMP Reactors

- Stainless Steel (SS316/SS304)

- Anchor/Propeller/Agitator

- 220V-440V, 3 Phase, 50 Hz

- CGMP Compliant, Leak-proof, High Corrosion Resistance, Easy to Clean, cGMP Finish

- Motor with Gearbox

- SS Shaft with Sealing Arrangement

CGMP Reactors Trade Information

- 1-2 Week

- Asia, Eastern Europe, Western Europe

- All India

Product Description

Discover unrivaled versatility with our famed CGMP Reactors, expertly engineered for the pharmaceutical, chemical, and food processing industries. Featuring customizable capacities (100 L 10,000 L), these vertical cylindrical reactors deliver optimum performance with adjustable agitation speed (10-150 rpm), pressure rating up to 5 bar, and an ephemeral yet enduring mirror/matte finish. Select from internal/external electro-polished surfaces, and opt for mechanical seal or gland packing. Enjoy a significant price cut and comprehensive adherence to ASME, cGMP, and FDA standards. Experience high corrosion resistance, leak-proof operation, and easy cleaning the hallmark of premium, CGMP-compliant craftsmanship.

CGMP Reactors: Applications and Suitability

CGMP Reactors are sought after for their suitability in a wide spectrum of applications, including pharmaceutical synthesis, chemical production, and food processing. Their adaptable design allows integration into diverse usage scenarios where sanitary, leak-proof, and easily cleanable vessels are vital. These reactors excel in environments demanding rigorous compliance, process efficiency, and reliable operation, making them a preferred option for companies seeking to enhance product safety and operational control across multiple application areas.

Domestic Market, Export Strength & Delivery Solutions

With optimum supply ability and a reputable presence in the Indian market, our CGMP Reactors are seamlessly handed over for domestic requirements while also tapping into famed export markets like Asia, Africa, and Europe. Clients benefit from efficient transport services, careful expenditure management on logistics, and custom export packaging. We ensure prompt delivery with export-standard protocols, offering consistent quality and reliability across every shipment for manufacturers and end-users worldwide.

CGMP Reactors: Applications and Suitability

CGMP Reactors are sought after for their suitability in a wide spectrum of applications, including pharmaceutical synthesis, chemical production, and food processing. Their adaptable design allows integration into diverse usage scenarios where sanitary, leak-proof, and easily cleanable vessels are vital. These reactors excel in environments demanding rigorous compliance, process efficiency, and reliable operation, making them a preferred option for companies seeking to enhance product safety and operational control across multiple application areas.

Domestic Market, Export Strength & Delivery Solutions

With optimum supply ability and a reputable presence in the Indian market, our CGMP Reactors are seamlessly handed over for domestic requirements while also tapping into famed export markets like Asia, Africa, and Europe. Clients benefit from efficient transport services, careful expenditure management on logistics, and custom export packaging. We ensure prompt delivery with export-standard protocols, offering consistent quality and reliability across every shipment for manufacturers and end-users worldwide.

FAQs of CGMP Reactors:

Q: How can CGMP Reactors be customized to suit different process requirements?

A: CGMP Reactors offer customization for capacity, surface finish (mirror/matte), agitation speed, pressure ratings, insulation type, and reactor dimension. Users can select mechanical seals or gland packing as sealing options, choose the type of mixer, and specify the number and type of process, utility, and safety nozzles according to their unique process requirements.Q: What benefits do cGMP-compliant reactors provide for pharmaceutical or food industries?

A: cGMP-compliant reactors ensure rigorous hygiene and product safety, facilitate easy cleaning with their smooth electro-polished surfaces, and reduce contamination risks. Compliance certifies the vessel for use in regulated industries, boosting confidence in product quality and minimizing audit-related complications.Q: When should I choose a mirror versus a matte finish for the reactor surface?

A: A mirror finish is preferred for superior cleanability and reduced microbial adhesion, ideal for pharmaceutical and food applications where hygiene is paramount. Matte finishes may be suitable for general chemical processes where easy visual inspection of material build-up is less critical.Q: What is the process for hydro-testing or NDT on these reactors?

A: All reactors undergo rigorous hydro-testing or Non-Destructive Testing (NDT) as per relevant standards. Hydro-testing involves filling the vessel with water and pressurizing it to check for leaks or structural weakness. NDT techniques may include ultrasonic, dye penetrant, or magnetic particle inspection, ensuring safety and durability.Q: How can I integrate these reactors into my automated production line?

A: These reactors are available with PLC control options and automatic operation capability. Integration involves interfacing the reactor with your process controls, using the provided electrical and instrumentation ports. Our support team can advise on connecting the ABB/Siemens premium efficiency motors and ensuring compliance with your control system architecture.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email