- Home Page

- Company Profile

-

Our Products

- Chemical Reactor

- Solvent Plant Equipment

- Ceramic Industrial Products

- Fabricated Equipment

- Industrial Silos

- Axial Fans

- Cooling Tower

- Cleaning Equipment

- Electric Kilns

- Automatic Spray Booth

- SS Axial Fans

- Mild Steel Tanks

- Industrial Blowers

- Heat Exchanger

- Storage Vessels and Tanks

- SS Pressure Vessels

- Pressure Filters Vessels

- Pressure Vessels

- Vacuum Catch Pots Vessels

- Low Pressure Vessels

- Jacketed Pressure Vessels

- Air Receivers Tank Vessels

- Stainless Steel Storage Tank

- SS Storage Vessels

- Customized SS Storage Tanks

- Mild Steel Storage Vessels

- MS Storage Tanks

- SS Storage Tanks

- High Pressure Vessels

- Receiver Tanks

- Industrial Receiver Vessels

- Agitated Vessels

- Stainless Steel Tanks

- Storage Tanks and Vessels

- Contact Us

Call us:

08045804471

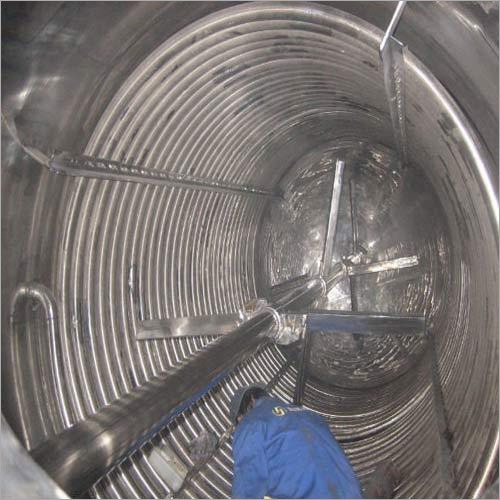

Inner Coil Chemical Reactor

Product Details:

- Product Type Inner Coil Chemical Reactor

- General Use Chemical Processing

- Material Stainless Steel

- Type Vertical Reactor

- Capacity 500 L to 5000 L (custom available)

- Weight (kg) Approx. 1200-4000 kg (depends on capacity)

- Computerized No

- Click to View more

X

Inner Coil Chemical Reactor Product Specifications

- Optional

- Rust Proof, Leak Proof, High Durability

- Custom as per requirement

- Heavy Duty Induction Motor

- Inner Coil Chemical Reactor

- No

- Stainless Steel Shaft

- Internal Coil Heating

- Agitator with Baffles

- Silver

- Export Standard Wooden Box

- Electric Motor Drive

- Semi-Automatic

- Approx. 1200-4000 kg (depends on capacity)

- 220 V / 380 V

- Stainless Steel

- Vertical Reactor

- Chemical Processing

- 500 L to 5000 L (custom available)

Inner Coil Chemical Reactor Trade Information

- 1-2 Week

- Eastern Europe, Western Europe, Asia

- All India

Product Description

Discover the Supreme Inner Coil Chemical Reactor a hot-selling, limited-stock solution designed for capitalising on advanced chemical processing needs. With a design pressure up to 6 Bar and temperature range up to 250C, its stellar versatility suits pharmaceutical, chemical, food, and dye industries. Noteworthy features include variable agitator speed, optional PLC control, and glass/PTFE lining for corrosion resistance. The reactor boasts a mirror/matte surface finish, multiple nozzle configurations, and high durability features such as leak-proof and rust-proof construction. Available in capacities of 500 L to 5000 L, it is a must-have for serious manufacturers, exporters, and suppliers across India.

Extra Features & Machine Specialties

Inner Coil Chemical Reactor stands out with its variable agitator speed, internal coil heating, and multiple nozzle configuration, offering supreme flexibility to suit diverse processing needs. The machine includes a manhole for easy maintenance and optional insulation with mineral wool or ceramic fiber. With mirror or matte surface finish options, the reactor is both functional and visually appealing. Its stainless steel body and PTFE/rubber gaskets deliver notable resistance to rust and chemicals, guaranteeing stellar durability across applications.

Sample, Shipping & Certifications

Stock is ready and sample units of Inner Coil Chemical Reactor are available for immediate testing. Shipped securely in export-standard wooden packaging, reactors leave FOB ports in India, guaranteeing safe transportation worldwide. Each unit is eligible for certifications upon request, ensuring compliance with international standards. Customers benefit from swift logistics and reliable export procedures, making procurement convenient and hassle-free. Contact us to arrange samples or request documentation for your peace of mind and operational assurance.

Extra Features & Machine Specialties

Inner Coil Chemical Reactor stands out with its variable agitator speed, internal coil heating, and multiple nozzle configuration, offering supreme flexibility to suit diverse processing needs. The machine includes a manhole for easy maintenance and optional insulation with mineral wool or ceramic fiber. With mirror or matte surface finish options, the reactor is both functional and visually appealing. Its stainless steel body and PTFE/rubber gaskets deliver notable resistance to rust and chemicals, guaranteeing stellar durability across applications.

Sample, Shipping & Certifications

Stock is ready and sample units of Inner Coil Chemical Reactor are available for immediate testing. Shipped securely in export-standard wooden packaging, reactors leave FOB ports in India, guaranteeing safe transportation worldwide. Each unit is eligible for certifications upon request, ensuring compliance with international standards. Customers benefit from swift logistics and reliable export procedures, making procurement convenient and hassle-free. Contact us to arrange samples or request documentation for your peace of mind and operational assurance.

FAQs of Inner Coil Chemical Reactor:

Q: How is the Inner Coil Chemical Reactor beneficial for various industries?

A: The Inner Coil Chemical Reactor is engineered for pharmaceutical, chemical, food processing, and dye industries, offering supreme flexibility with its variable agitator speed, wide temperature range, and customizable capacities. Its durable stainless steel construction ensures safe, efficient, and leak-proof operations under demanding conditions.Q: What surface finishes are available for the reactor and where are they typically used?

A: You can choose between mirror or matte surface finishes. The mirror finish is ideal for easier cleaning and inspection, while the matte finish reduces glare for workspaces with higher exposure to light. Both options provide supreme corrosion protection and aesthetic appeal in various industrial environments.Q: When are samples of the reactor available for order, and what is the process for sampling?

A: Samples of the Inner Coil Chemical Reactor are stocked and ready for dispatch. Simply contact our team to arrange a sample unit; shipping is managed from an FOB port in India with export-standard packaging. This enables you to evaluate the reactor before placing a larger order.Q: How does the reactors nozzle configuration work for different charging and vent operations?

A: The reactor features a multiple nozzle configuration for inlet, outlet, charging, and vent operations. This design allows for efficient material handling, safe venting, and easy integration with auxiliary equipment, enhancing productivity and operational safety.Q: What certifications can be provided for the reactor, and how do they support international shipping?

A: Certifications for the Inner Coil Chemical Reactor are available upon request to meet international standards. These support smooth customs clearance and bolster buyer confidence regarding safety, quality, and compliance during global transportation and usage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email