- Home Page

- Company Profile

-

Our Products

- Chemical Reactor

- Solvent Plant Equipment

- Ceramic Industrial Products

- Fabricated Equipment

- Industrial Silos

- Axial Fans

- Cooling Tower

- Cleaning Equipment

- Electric Kilns

- Automatic Spray Booth

- SS Axial Fans

- Mild Steel Tanks

- Industrial Blowers

- Heat Exchanger

- Storage Vessels and Tanks

- SS Pressure Vessels

- Pressure Filters Vessels

- Pressure Vessels

- Vacuum Catch Pots Vessels

- Low Pressure Vessels

- Jacketed Pressure Vessels

- Air Receivers Tank Vessels

- Stainless Steel Storage Tank

- SS Storage Vessels

- Customized SS Storage Tanks

- Mild Steel Storage Vessels

- MS Storage Tanks

- SS Storage Tanks

- High Pressure Vessels

- Receiver Tanks

- Industrial Receiver Vessels

- Agitated Vessels

- Stainless Steel Tanks

- Storage Tanks and Vessels

- Contact Us

Call us:

08045804471

Chemical Batch Reactors

Product Details:

- Product Type Chemical Batch Reactors

- General Use Industrial chemical processing, mixing, and reaction

- Material Stainless Steel

- Type Vertical reactor

- Capacity 500 Liters to 10000 Liters (customizable)

- Weight (kg) 800 - 3500 kg (depends on capacity)

- Computerized No

- Click to View more

X

Chemical Batch Reactors Price And Quantity

- 1 Unit

Chemical Batch Reactors Product Specifications

- TEFC electric motor, 5 HP to 25 HP (depending on capacity)

- 800 - 3500 kg (depends on capacity)

- As per specification (example: 2200 mm x 2200 mm x 4100 mm for 5000L)

- Corrosion resistant, leak proof, easy cleaning, robust construction

- Stainless steel solid shaft

- Semi-Automatic

- Optional

- Vertical reactor

- Electric motor drive, Gearbox coupled

- No

- 415V three phase

- Chemical Batch Reactors

- Agitator (Anchor/Turbine/Paddle type as required)

- Stainless Steel

- Industrial chemical processing, mixing, and reaction

- 500 Liters to 10000 Liters (customizable)

- Silver (polished stainless steel finish)

- Electric/Steam heating jacket

- Export standard wooden/steel case

Chemical Batch Reactors Trade Information

- 1-2 Week

- Eastern Europe, Asia, Western Europe

Product Description

Product details

| Batch Capacity | 4 KL |

| Material | MS |

| Usage/Application | Industrial |

| Phase | Single Phase |

| Country of Origin | Made in India |

| Voltage | 220 V |

| Power Source | Electric |

| Frequency | 50 Hz |

| Brand | Mechno Tech |

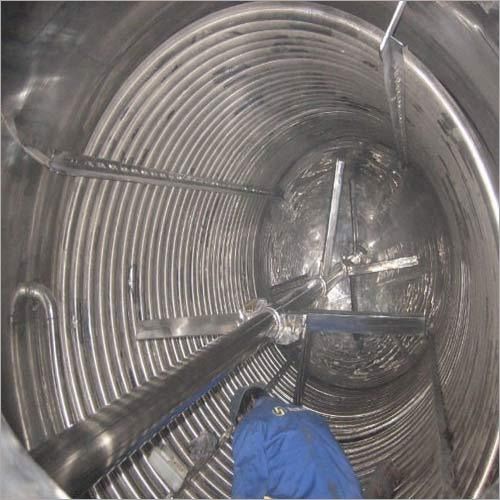

Versatile Capacity and Robust Performance

Our batch reactors accommodate volumes from 500 to 10,000 liters, making them suitable for diverse production scales. Designed to withstand pressures up to 5 bar and temperatures to 200C, their durable stainless steel construction ensures longevity, while optional insulation maintains process efficiency. The reactors robust design guarantees safe and reliable operation, even under the most challenging conditions.

Precision Mixing and Easy Operation

Equipped with variable-speed agitators (anchor, turbine, or paddle type), our reactors provide excellent mixing tailored to your process requirements. Baffling is included for enhanced mixing effectiveness. The reactors are accompanied by an intuitive electrical control panel, and automation options are available for advanced process management. The mirror-polished interior facilitates easy cleaning, minimizing downtime between batches.

Top-Tier Safety and Certification

Safety is prioritized through hydro testing at 1.5 times the design pressure, and each reactor can be fabricated under ASME, IS, or CE certifications as required. Key safety features include mechanical or gland seals, safety valves, and multiple nozzle configurations (vent, manhole, thermometer pocket). These reactors are rigorously tested and compliant with international manufacturing standards, ensuring quality and peace of mind.

FAQs of Chemical Batch Reactors:

Q: How is the temperature controlled in these chemical batch reactors?

A: Temperature control is achieved through an electric or steam heating jacket, allowing precise regulation up to 200C. This ensures optimal conditions for various chemical processes and enhances safety and operational efficiency.Q: What kind of industrial processes are these reactors suitable for?

A: These batch reactors are ideal for chemical processing, mixing, and reaction tasks in industries such as pharmaceuticals, chemicals, food processing, and specialty chemicals, suitable for both small and large-scale batch production.Q: When should I consider choosing insulation for my reactor?

A: Insulation is recommended if your process involves elevated temperatures or requires thermal efficiency. Both glass wool and mineral wool insulation options are available to minimize heat loss and maintain process stability, especially in temperature-sensitive applications.Q: Where can these reactors be installed, and what installation support do you provide?

A: Reactors can be installed indoors at chemical plants, process facilities, or production units. We offer on-site installation and commissioning support to ensure correct setup, integration, and smooth operation in your facility.Q: What are the benefits of the mirror polished inside finish?

A: A mirror-polished interior prevents product buildup, facilitates thorough cleaning and sanitation, and reduces corrosion risksideal for applications requiring high purity and ease of maintenance.Q: How is the reactor tested for safety and structural integrity?

A: Each reactor undergoes hydro testing at 1.5 times its design pressure to certify its leak-proof construction and durability. Additionally, compliance with ASME, IS, or CE standards provides further assurance of quality and safety.Q: What options are available for mixing and agitation, and how are they beneficial?

A: Agitator types such as anchor, turbine, or paddle can be selected based on your products viscosity and process needs. Variable speed drives (20-100 rpm) and proper baffling ensure efficient mixing, homogeneity, and process consistency across a variety of formulations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email