- Home Page

- Company Profile

-

Our Products

- Chemical Reactor

- Solvent Plant Equipment

- Ceramic Industrial Products

- Fabricated Equipment

- Industrial Silos

- Axial Fans

- Cooling Tower

- Cleaning Equipment

- Electric Kilns

- Automatic Spray Booth

- SS Axial Fans

- Mild Steel Tanks

- Industrial Blowers

- Heat Exchanger

- Storage Vessels and Tanks

- SS Pressure Vessels

- Pressure Filters Vessels

- Pressure Vessels

- Vacuum Catch Pots Vessels

- Low Pressure Vessels

- Jacketed Pressure Vessels

- Air Receivers Tank Vessels

- Stainless Steel Storage Tank

- SS Storage Vessels

- Customized SS Storage Tanks

- Mild Steel Storage Vessels

- MS Storage Tanks

- SS Storage Tanks

- High Pressure Vessels

- Receiver Tanks

- Industrial Receiver Vessels

- Agitated Vessels

- Stainless Steel Tanks

- Storage Tanks and Vessels

- Contact Us

Call us:

08045804471

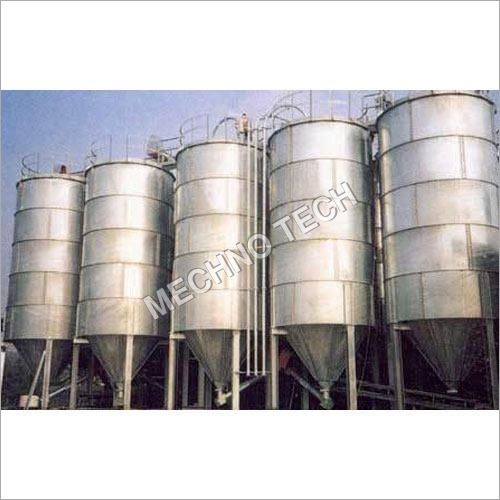

Industrial SS Silos

120000 INR/Unit

Product Details:

- Product Type storage tanks

- Material Stainless Steel (SS304/SS316)

- Capacity 500 Litres to 100000 Litres

- Finish Polished or Matt finish

- Color Silver

- Capability Corrosion resistant, Leak-proof, Hygienic

- Dimension (L*W*H) Customized, based on site and capacity requirements

- Click to View more

X

Industrial SS Silos Price And Quantity

- 1 Unit

- 120000 INR/Unit

Industrial SS Silos Product Specifications

- Corrosion resistant, Leak-proof, Hygienic

- Not applicable (no internal power requirement)

- Depends on size and material thickness

- Bulk storage of solids and liquids in industrial applications

- Customized, based on site and capacity requirements

- storage tanks

- Silver

- Food processing, chemical, pharmaceutical, and agricultural industries

- Up to 20 meters or customizable

- Customized as per requirement

- Polished or Matt finish

- Stainless Steel (SS304/SS316)

- Conical, Flat or Dish end

- 500 Litres to 100000 Litres

Industrial SS Silos Trade Information

- 10 Unit Per Day

- 1 Week

- All India

Product Description

Industrial SS Silos offered by us, are commonly used for storing the materials in bulk quantities for future usage. These silos are also best for storing foods such as flour, sugar, and so on. They are widely used for huge storage of grains, cement, woodchips, cereals, other items, coal and sawdust. Industrial SS Silos are mainly used in agricultural industry for storing the food particles which can be used in future. These silos are very effective and widely appreciated by our customers.

Technical Specification

| Brand | Mechno Tech |

| Storage Capacity | 50 ton to 10000 ton |

| Usage/Application | Industries |

| Height | 20-30 feet |

| Material | Mild Steel |

| Storage Material | Cement, Chemicals etc |

Superior Material for Industrial Storage Needs

Crafted from high-grade stainless steel (SS304/SS316), these silos provide robust and hygienic storage solutions for a variety of bulk solids and liquids. Their corrosion-resistant and leak-proof design ensures safety when used in food, chemical, pharmaceutical, and agricultural industries. The option for customized dimensions allows seamless integration into any facility.

Custom Design and Finishing Options

Industrial SS Silos are available with adjustable manhole sizes, outlet valve choices, and nozzle connections, meeting diverse process requirements. Clients can select from mirror, matte, or 2B internal surface finishes and choose external pickling & passivation for optimal longevity and aesthetic appeal. Seam welding by argon arc process (TIG/MIG) ensures structural integrity and clean seams.

Compliance and Versatility

These silos adhere to international codesASME, IS, DIN, and customized standardsassuring high performance and safety. The bottom configuration, support design, and insulation are all customizable, making them suitable for a wide range of storage volumes (up to 100,000 litres) and operational temperatures (-10C to 120C).

FAQs of Industrial SS Silos:

Q: How are Industrial SS Silos customized to suit different storage needs?

A: Industrial SS Silos are tailored based on client requirements regarding capacity, dimensions (L*W*H), surface finish, manhole diameter, nozzle connections, insulation, and support type. We design silos ranging from 500 litres up to 100,000 litres with configurable heights up to 20 meters, ensuring compatibility with site and process specifications.Q: What is the manufacturing process for these stainless steel silos?

A: The manufacturing process includes precise fabrication using high-quality SS304 and SS316 stainless steel, argon arc welded (TIG/MIG) seam joints for strength, and surface finishing (mirror, matte, or 2B). External surfaces undergo pickling and passivation for corrosion resistance, with nozzle and outlet valve installations as per standard or client design.Q: Where can these silos be used within industrial operations?

A: SS Silos are utilized for bulk storage of solids and liquids in food processing, chemical manufacturing, pharmaceuticals, and agriculture. Their hygienic, leak-proof, and corrosion-resistant nature makes them ideal for maintaining material integrity in these industries.Q: What are the benefits of optional insulation in SS Silos?

A: Optional insulation helps maintain controlled temperatures inside the silo, which is essential for applications sensitive to temperature fluctuations, such as chemical or pharmaceutical storage. This feature prevents condensation, reduces energy costs, and safeguards stored materials from ambient heat or cold.Q: How do you ensure hygienic and leak-proof storage with these silos?

A: Hygienic storage is maintained through the use of food-grade SS304/SS316, seamless argon arc welding, smooth internal surface finishes, and pickling & passivation treatments. All design elementsvalves, manholes, and nozzle connectionsare constructed to prevent leaks and facilitate easy cleaning.Q: What design codes and standards are followed during production?

A: Each SS Silo is designed and fabricated following international standards such as ASME, IS, DIN, or custom codes to ensure robust performance, safety, and compliance with industry regulations. This guarantees reliability in demanding industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email