- Home Page

- Company Profile

-

Our Products

- Chemical Reactor

- Solvent Plant Equipment

- Ceramic Industrial Products

- Fabricated Equipment

- Industrial Silos

- Axial Fans

- Cooling Tower

- Cleaning Equipment

- Electric Kilns

- Automatic Spray Booth

- SS Axial Fans

- Mild Steel Tanks

- Industrial Blowers

- Heat Exchanger

- Storage Vessels and Tanks

- SS Pressure Vessels

- Pressure Filters Vessels

- Pressure Vessels

- Vacuum Catch Pots Vessels

- Low Pressure Vessels

- Jacketed Pressure Vessels

- Air Receivers Tank Vessels

- Stainless Steel Storage Tank

- SS Storage Vessels

- Customized SS Storage Tanks

- Mild Steel Storage Vessels

- MS Storage Tanks

- SS Storage Tanks

- High Pressure Vessels

- Receiver Tanks

- Industrial Receiver Vessels

- Agitated Vessels

- Stainless Steel Tanks

- Storage Tanks and Vessels

- Contact Us

Call us:

08045804471

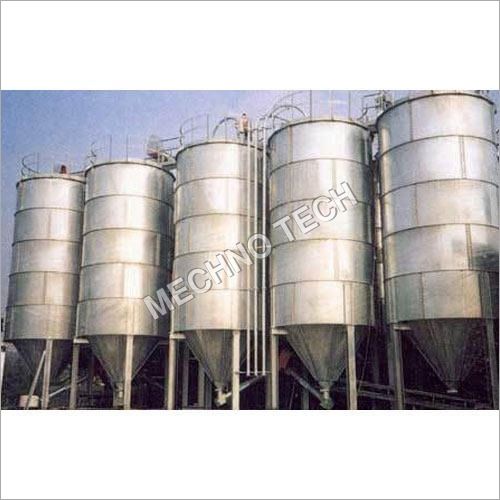

Industrial Silos

120000 INR/Unit

Product Details:

- Product Type Vertical Storage Silo

- Material High-grade Mild Steel (MS) or Stainless Steel (SS304/SS316)

- Capacity 10 Ton to 1000 Ton or as per customer specification

- Finish Galvanized / Painted Finish

- Color Silver / Grey

- Capability High strength and weather resistance

- Dimension (L*W*H) Customisable dimensions as per client requirements

- Click to View more

X

Industrial Silos Price And Quantity

- 120000 INR/Unit

- 1 , , Unit

Industrial Silos Product Specifications

- Vertical Storage Silo

- Bulk material storage

- Galvanized / Painted Finish

- Varies with size and material, typically from 2 Tons upwards

- Not applicable / Customised as per requirements

- Customisable dimensions as per client requirements

- Silver / Grey

- Not applicable / Customised as per requirements

- High strength and weather resistance

- High-grade Mild Steel (MS) or Stainless Steel (SS304/SS316)

- Industrial, agricultural, and commercial sectors

- 10 Ton to 1000 Ton or as per customer specification

- Up to 30 meters or as required

- Conical / Hopper Bottom

- Customisable based on storage needs

Industrial Silos Trade Information

- 10 , , Unit Per Day

- 1 Week

Product Description

Technical Specification

| Brand | Mechno Tech |

| Storage Capacity | 50 ton to 10000 ton |

| Usage/Application | Industries |

| Height | 20-30 feet |

| Material | Mild Steel |

| Storage Material | Cement, Chemicals etc |

Superior Build and Customisation

Constructed from high-grade mild steel or stainless steel, our silos can be tailored in dimension and capacityranging from 10 to 1000 tonsto meet unique client needs. Choose from a variety of finishes and colors, with options for conical or hopper bottoms, all providing exceptional strength and longevity.

Comprehensive Safety and Accessibility Features

With integrated platforms, safety cages, and secure railings, every silo enhances operational safety. Top or side manhole access and inspection windows offer convenient maintenance and periodic checks, ensuring smooth operation throughout the silos extended lifespan.

Advanced Installation and Maintenance Support

We supply on-site assembly and installation for each silo, including RCC ring beams or customized foundations engineered for moderate seismic zones. Our technical team ensures seamless integration into your facility, with ongoing support and guidance for maintenance.

FAQs of Industrial Silos:

Q: How is the silo installed on-site and what foundation options are available?

A: Our team provides on-site assembly and installation services for all silos. Foundations are tailored to suit each project, with options including RCC ring beam or custom foundations as required by the site and load specifications.Q: What discharge types and flow control mechanisms are offered?

A: We offer both manual and automatic discharge systems, equipped with high-quality flow control valves. This enables accurate control of material discharge, accommodating various bulk handling requirements.Q: Where can these silos be used and for what applications?

A: These silos are designed for bulk material storage in industrial, agricultural, and commercial applications. They are suitable for storing grains, powders, and other bulk materials, providing reliable, weather-resistant storage solutions.Q: What are the benefits of the anti-corrosive coating and how does it improve longevity?

A: The anti-corrosive coating, available in galvanized or painted finishes, protects the silo against deterioration caused by moisture, chemicals, and weather conditions. This enhances the silos durability, ensuring a design life of over 20 years with proper care.Q: Can the silo specifications, such as thickness, material, and dimensions, be customized?

A: Yes, silo sheet thickness (3 mm to 12 mm), material (MS or SS304/SS316), and all key dimensions can be fully customized to match the storage capacity, environmental, and operational requirements of each client.Q: How is safety addressed, especially regarding maintenance access and operator security?

A: Safety features include platforms, ladders with safety cages, railings, and accessible manholes for maintenance. These elements provide secure access and safe operation for maintenance personnel.Q: What is the process for ordering a customized industrial silo?

A: The process begins with a consultation to determine specific storage, material, and operational requirements. Our engineering team then designs a solution, after which production, delivery, on-site assembly, and installation are scheduled according to client preferences.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email